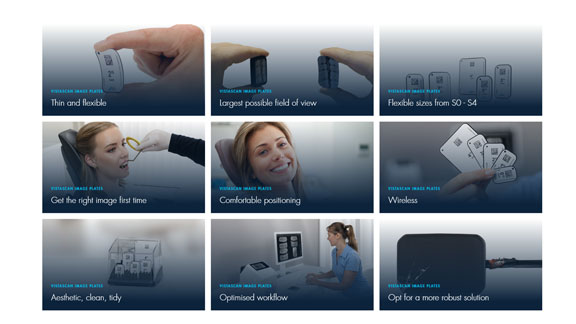

Advantages of VistaScan

VistaScan Image Plates – optimised workflow

When looking at the general workflow, sensors offer no overall time advantages.

The time from exposure to the display of the image on the screen is very fast on sensors.

On image plates an additional step is required to digitise the image information using a VistaScan Image Plate scanner. For this reason, a sensor may appear at first glance to be the faster solution.*

However, it soon becomes clear that this is not the case if we look at the overall workflow as a whole.

- Preparation: sensors may need to be collected from their storage location and carefully disentangled. In addition, they also need to be packed in a hygienic protective cover immediately before they are used and connected to a USB port.

- Positioning in the mouth of the patient: this takes longer than with image plates, as it is more difficult and the cable gets in the way. Increased risk that images will need to be retaken.

- Steps after image acquisition: the hygienic protective cover needs to be removed, the entire cable needs to be disinfected, the cable needs to be carefully coiled up, and everything needs to be taken to its storage location (more space required for storage).

*After all, in cases in which the X-ray unit is located in a central X-ray room the advantage that sensors offer in terms of the short time between image exposure and the image appearing on the screen is completely irrelevant because the time taken by the patient to go back to the treatment room completely negates any gains. In these situations, image plate technology can actually be faster overall.

✔ Overall the workflow with image plates is smoother and simpler

✔ Ready to use – storage in the image plate storage box

✔ Save time and reduce stress